g code list pdf

G-Code is the standard CNC programming language, developed in the 1950s at MIT․ It uses codes and numbers to instruct machines, serving as the backbone of modern manufacturing for precise operations․

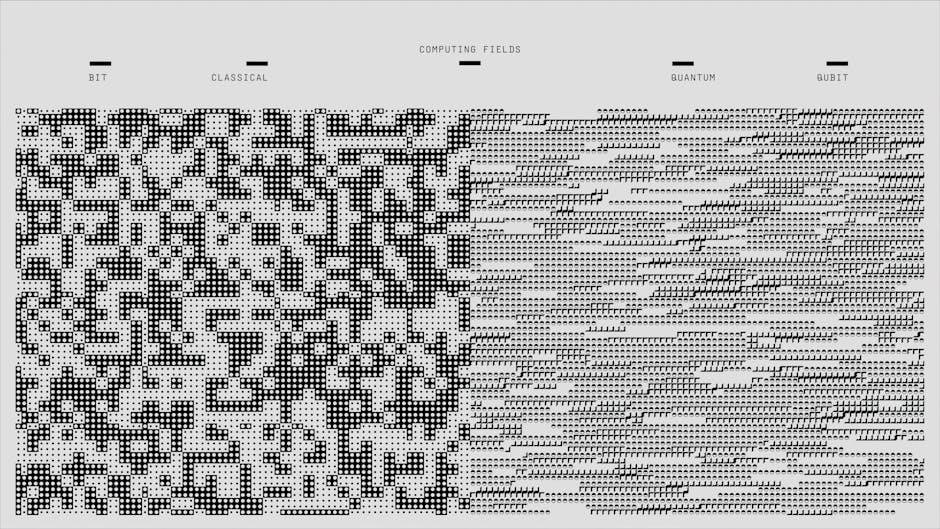

1․1 What is G-Code?

G-Code is the standard programming language for CNC machines, instructing them on precise operations․ It uses codes like G00, G01, and M03 to control movements and functions․ Developed in the 1950s, it remains essential for manufacturing․ G-Code consists of letter and number blocks, with G and M being primary letters․ Despite its simplicity, it’s widely used due to its effectiveness․ Resources like G-Code lists and PDF guides provide detailed instructions for programmers, ensuring accurate machining processes across industries․

1․2 Importance of G-Code in CNC Machining

G-Code is fundamental to CNC machining, enabling precise control of machine tools․ It standardizes operations, ensuring compatibility across different devices․ Its use simplifies complex tasks, allowing for automated manufacturing․ G-Code’s importance lies in its ability to enhance productivity, reduce errors, and facilitate intricate designs․ Industries rely on it for consistency and efficiency․ Resources like G-Code lists and guides are essential for programmers, ensuring accurate execution․ Its widespread adoption underscores its critical role in modern manufacturing, making it indispensable for achieving high-precision results․

1․3 Brief History of G-Code Development

G-Code originated in the 1950s at MIT, developed for early CNC systems․ Initially primitive, it used codes like G01 for commands․ Over time, it evolved to include M-codes and canned cycles, improving functionality․ Fanuc’s contributions further standardized G-Code, making it widely adopted․ Its simplicity and modal nature allowed for efficient programming․ Today, G-Code remains essential for CNC machining, with resources like G-Code lists and tutorials aiding programmers․ Its enduring relevance is a testament to its foundational role in manufacturing technology․

List of Common G-Codes

Common G-codes include G00, G01, G02, and G03 for basic movements․ These codes are essential for CNC machining, providing precise instructions․ A complete G-code list PDF is available for reference․

2․1 Basic G-Codes for Movement (G00, G01, G02, G03)

G00 is the rapid positioning code, moving the tool quickly without cutting․ G01 performs linear interpolation for cutting motions․ G02 and G03 handle circular interpolation for clockwise and counterclockwise arcs․ These codes are fundamental for CNC machining, enabling precise control of tool movements․ A complete G-code list PDF provides detailed explanations and examples of these essential commands, ensuring accurate programming for various operations․

2․2 Specialized G-Codes for Advanced Operations

Specialized G-codes enable advanced CNC operations, such as drilling and tapping․ Codes like G81 to G89 handle various drilling cycles, while G76 is used for threading․ These codes simplify complex tasks by automating sequences, reducing manual programming effort․ A complete G-code list PDF provides detailed explanations, ensuring programmers can utilize these codes effectively for precise and efficient machining․ These advanced commands are essential for achieving high-quality finishes and meeting specific manufacturing requirements․

2․3 Modal vs․ Non-Modal G-Codes

Modal G-Codes remain active until canceled, while Non-Modal G-Codes execute once․ Modal codes, like G01, maintain their function until overwritten, ensuring continuous operation․ Non-Modal codes, such as G04 for dwell, perform a single action․ Understanding this distinction is crucial for efficient CNC programming, as Modal codes streamline operations by reducing repetitive commands, whereas Non-Modal codes offer precise control for specific tasks․ This fundamental difference enhances programming flexibility and accuracy in machining processes․

M-Code Functions in CNC Programming

M-Codes control machine functions like tool changes, coolant activation, and spindle operations․ They work alongside G-Codes to manage auxiliary operations, ensuring efficient and precise CNC machining processes․

3․1 Overview of M-Codes

M-Codes are supplementary codes in CNC programming that control machine-specific functions beyond movement․ They manage operations like spindle start/stop, coolant activation, and tool changes․ Unlike G-Codes, M-Codes are not movement-oriented but ensure smooth machine operation․ They are often specific to machine types, making them crucial for precise control in manufacturing processes․ A comprehensive list of M-Codes is essential for understanding their applications and optimizing CNC machining workflows․

3․2 Common M-Codes for Machine Control

M-Codes are used to control machine functions such as spindle rotation, coolant activation, and tool changes․ Common codes include M03 (spindle clockwise) and M04 (spindle counterclockwise)․ M08 activates coolant, while M09 turns it off․ M06 is used for tool changes, and M30 ends a program, resetting the machine․ These codes ensure precise control over machine operations, enabling efficient and safe manufacturing processes․ Referencing a complete M-Code list is essential for understanding their specific applications and ensuring compatibility with different CNC systems․

Canned Cycles in G-Code

Canned cycles simplify repetitive operations like drilling and tapping․ G81 is for drilling, G82 for counterboring, and G83 for peck drilling․ These cycles improve efficiency in CNC machining․

4․1 G-Code Canned Cycles for Drilling and Tapping

Canned cycles are pre-defined G-Code functions for repetitive tasks․ G81 is used for drilling operations, specifying coordinates and depth․ G82 is for counterboring, while G83 handles peck drilling․ G84 is designed for tapping, automating thread cutting․ These cycles simplify programming by reducing manual code input․ They improve efficiency in CNC machining by streamlining operations like hole drilling and tapping․ Canned cycles are essential for manufacturers needing precise, repetitive tasks․ They ensure consistency and reduce errors in production processes․ G-Code lists provide detailed parameters for each cycle, enabling accurate implementation․ These tools are vital for optimizing CNC machining workflows and productivity․

4․2 Applications of Canned Cycles in CNC Machining

Canned cycles are widely used in CNC machining for repetitive operations like drilling, tapping, and milling․ They enhance efficiency by automating tasks, reducing programming time, and minimizing errors․ Common applications include manufacturing, aerospace, and automotive industries, where precise hole drilling and tapping are critical; These cycles are particularly useful for complex geometries and large production runs․ By standardizing operations, canned cycles ensure consistency and accuracy, making them indispensable in modern manufacturing workflows․ They simplify programming, allowing machinists to focus on complex tasks while ensuring reliable results․

G-Code Examples and Tutorials

G-Code examples and tutorials provide step-by-step guides for programming CNC machines․ They cover simple to advanced programs, helping users master G-Code basics and complex applications effectively․

5․1 Simple G-Code Programs for Beginners

Simple G-Code programs are essential for newcomers to CNC programming․ These programs typically involve basic movements like linear and circular interpolation, often used for drilling or milling․ They help learners grasp fundamental commands such as G00, G01, and G02․ By practicing these examples, beginners can understand how G-Code instructs machines to perform specific tasks․ Many resources provide downloadable PDF guides with explanations, ensuring a smooth learning curve․ These tutorials are crucial for building a strong foundation in CNC programming before advancing to more complex operations․

5․2 Advanced G-Code Examples

Advanced G-Code examples demonstrate complex machining operations, such as multi-axis movements and custom macros․ These programs often incorporate canned cycles for efficiency and precision․ For instance, helical interpolation (G02/G03) is used for creating complex curves․ Macros enable parameterized programming, reducing code length․ Applications include advanced drilling patterns, threading (G76), and high-speed machining (G05)․ These examples showcase how G-Code can optimize production processes․ They are invaluable for experienced programmers aiming to enhance productivity and achieve intricate part geometries․ Practicing these examples helps master advanced CNC techniques and improve overall machining accuracy․

G-Code Resources and References

The complete G-Code list PDF provides a detailed guide for CNC programming․ It includes tutorials, examples, and explanations of functions and applications, aiding both beginners and experts․

6․1 Complete G-Code List PDF

A complete G-Code list PDF provides a comprehensive guide to understanding and implementing G-Codes in CNC programming․ It includes detailed explanations of each G-Code, their functions, and applications․ The PDF covers modal and non-modal codes, as well as examples of how to use them in various machining operations․ It also lists the most commonly used G-Codes for milling and turning, making it an essential resource for both beginners and experienced programmers․ This document is widely used as a reference for understanding G-Code programming in different CNC controllers, including Fanuc and Haas systems․

6․2 Recommended Tutorials and Guides

Various tutorials and guides are available to help learners master G-Code programming․ Online resources include video tutorials, PDF manuals, and interactive courses․ These materials cover topics like basic G-Code syntax, advanced machining operations, and the use of M-Codes․ Websites and forums dedicated to CNC programming often provide step-by-step guides and practical examples․ These resources are ideal for both beginners and experienced programmers looking to refine their skills․ They offer a structured approach to learning G-Code, ensuring a solid foundation for real-world applications in CNC machining․

Related Posts

five rites of rejuvenation pdf

Discover the ancient Tibetan secrets to a younger, healthier you! Download the ‘5 Rites of Rejuvenation’ PDF and start your journey to incredible energy & well-being today. ✨

the clean house by sarah ruhl pdf

Download Sarah Ruhl’s ‘The Clean House’ in PDF format! Explore this Pulitzer Prize finalist – a quirky, funny, and deeply moving play about love, loss, and cleaning. Get your copy now!

fifty shades of grey book free pdf

Dive back into the passionate world of Christian Grey! Download the *Fifty Shades Freed* PDF now and experience the thrilling conclusion. Free & easy access!